Choose an electric hoist or winch?

Choose an electric hoist or winch?

Electric hoists and electric winches are two common types of lifting equipment, they have many similarities in shape and working principle, so many customers often confuse electric hoists and winches when buying equipment, but as two different kinds of lifting machinery, what are the differences between electric hoists and electric winches?

This paper will focus on the definition, characteristics, working principles, application fields, and other aspects of electric hoist and electric hoist to help customers better understand and distinguish between the two devices.

Definition of electric hoist:

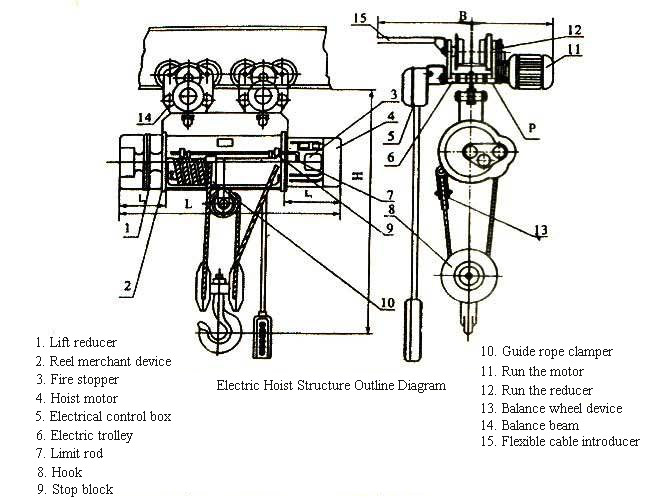

An electric hoist is a kind of mechanical equipment for lifting and handling items, divided into wire rope electric hoist and chain electric hoist, is a light small lifting equipment. It can be driven by the motor to rotate the drum, so that the steel wire rope or chain lift, plays the role of lifting and transporting goods. The electric hoist is usually composed of a motor, a reducer, a reel, a walking mechanism, a controller, etc., which can be operated on the ground by using a button, or can also be operated in the driver's room or controlled remotely by wired (wireless).

Definition of electric winch:

The winch is a device that is driven by manpower or mechanical power and winds a rope to complete the pulling work. Heavy objects can be lifted vertically, horizontally, or tilted. For the lifting height and loading and unloading of large work frequently, the speed regulation performance is good, which can make the hook quickly fall. Compared with the electric hoist, its carrying capacity is greater.

First of all, they have many similarities in form and working principle, but there are differences in carrying capacity, structure, price and so on. In the selection, the appropriate equipment should be selected according to the actual needs.

Different carrying capacity: The carrying capacity of the electric hoist is usually less than 10 ton, while the carrying capacity of the electric winch can reach tens of tons.

10 ton electric hoist parameter table:

| Capacity | t | 10 | |||||

| Hoisting speed | m/min | 7 | |||||

| Travel speed | m/min | 20、30 | |||||

| Lifting motor | Type | ZD1 51-4/13kw | |||||

| Operation motor | Type | ZDY1 21-4/0.8kw×2 | |||||

| Track | 32b~50b | ||||||

| Wire rope | Dia.(mm) | 15 | |||||

| Specification | 6×37+FC | ||||||

| Hoisting height | m | 6 | 9 | 12 | 18 | 24 | 30 |

| Min curvature radius | m | 3.5 | 4 | 6 | 7.5 | 9 | |

| Weight(Operation type) | kg | 1048 | 1098 | 1209 | 1301 | 1411 | |

| Weight(Stationary type) | kg | 795 | 841 | 943 | 1035 | 1127 | |

Electric hoist parameter table:

| Model | Rated load (KN) | Rated speed | Rope capacity (m) | rope diameter | Electromotor type |

| JM1 | 10 | 15 | 100 | Φ9.3 | Y112M-6 |

| JM1.6 | 16 | 16 | 150 | Φ12.5 | Y132M2-6 |

| JM2 | 20 | 16 | 150 | Φ13 | Y160M-6 |

| JM3.2 | 32 | 9.5 | 150 | Φ15.5 | YZR160M2-6 |

| JM3.2B | 32 | 12 | 195 | Φ15.5 | YZR160M2-6 |

| JM5 | 50 | 10 | 270 | Φ21.5 | YZR160L-6 |

| JM5B | 50 | 9.5 | 200 | Φ21.5 | YZR160L-6 |

| JM5C | 50 | 9.5 | 250 | Φ21.5 | YZR160L-6 |

| JM5D | 50 | 15 | 250 | Φ21.5 | YZR180L-6 |

| JM5E | 50 | 20 | 250 | Φ21.5 | YZR200L-6 |

| JM6 | 60 | 9.5 | 270 | Φ24 | YZR180L-6 |

| JM8 | 80 | 8 | 250 | Φ26 | YZR180L-6 |

| JM8B | 80 | 9.5 | 350 | Φ26 | YZR180L-6 |

Different structure: The electric hoist has a simple structure, small size, lightweight, and suitable for light lifting; the electric winch has a complex structure, large volume, and heavy weight, which is suitable for heavy lifting.

Price is different: The price of electric hoist is relatively low, suitable for small enterprises or personal use; the price of electric winch is higher, suitable for large enterprises or engineering projects.

Secondly, there are obvious differences between the hoist and the electric winch in five aspects: operation mode, operation speed, lifting height, appearance, and use.

1. In terms of operation mode, the electric hoist can be translated left and right, and the winch can only be fixed.

2. In terms of speed of improvement, the basic lifting speed of the general electric hoist is 8M per minute, and the slow speed of the winch is generally about 10M per minute, which is determined according to the weight and model.

3. In terms of lifting height, the lifting height of the wire rope electric hoist is usually 6M to 12M. Because the installation of steel wire rope is not convenient, the installation of steel wire rope will bring a series of related problems (after the installation of steel wire rope, the volume of the drum of the whole gourd will change). The lifting height of the winch depends only on the capacity of its drum, which is generally about 100M.

4. In appearance, The electric hoist is small in size and needs to be installed on the I-beam; Although the volume of the winch is slightly larger, it can be used fixed;

5. In terms of use, the electric hoist can only be used for lifting operations, and the winch can not only be used for lifting, but also for traction and other operations.

Finally, we distinguish and compare the working principle and application field of electric hoist and electric winch.

The working principle of the electric hoist: First start the lifting motor, lift the weight to the appropriate height, and then start the running motor to transport the weight to the designated position, and the running trolley walks on the lower edge of the I-beam. When walking, an electric motor drives the wheels on both sides of the trolley. Because the traveling speed is relatively small, the running car generally does not have a braking mechanism. In order to prevent heavy objects from falling, an electromagnetic brake is set on the lifting mechanism. The circuit of the electromagnetic brake is in parallel with the circuit of the lifting motor, so as long as the lifting motor starts, the electromagnetic brake is released, so that the heavy object can rise and fall freely; When the motor is closed, the electromagnetic brake is also powered off, the electromagnetic attraction disappears, and under the pressure of the spring, the inner and outer disks are tightly pressed to play the role of braking.

The working principle of electric winch: It is mainly driven by external forces (such as electric motors), and then controlled by electromagnetic brakes and lock brakes in the absence of free operation, at the same time, driven by the motor, a roulette wheel is driven.

Application Area:

Application fields of electric hoist: Electric hoist is suitable for light lifting and handling, such as factories, warehouses, docks, logistics centers and so on. Common application scenarios include machining, loading and unloading cargo, and maintaining equipment.

Application fields of electric winch: Electric winch is suitable for heavy lifting and handling, such as mines, ports, construction sites, large buildings, and so on. Common application scenarios include construction sites, mining, and ship loading and unloading.

The above comparison is limited to general circumstances, if you want to know more about the difference between electric hoist and electric hoist, please consult us!

- Previous: How to Properly Use Lifting Sling with Hooks

- Next: None