Innovative Uses of Butterfly Valves: Are They Transforming Industries?

## Butterfly Valves: Transforming Industries.

Butterfly valves are versatile flow control devices commonly used in various industries. Their innovative designs and functionalities have transformed many processes, leading to improved efficiency and productivity. In this article, we will explore some of the innovative uses of butterfly valves and how they are revolutionizing industries.

### 1. Water Treatment Plants.

Water treatment plants rely on butterfly valves for controlling the flow of water and chemicals in different treatment processes. Butterfly valves are ideal for regulating the flow of liquids and slurries, making them essential in the treatment of drinking water and wastewater. Their robust construction and corrosion-resistant materials ensure reliable operation in harsh environments.

### 2. HVAC Systems.

### 3. Oil and Gas Industry.

Additional reading:The Advantages of Installing Solar Panels in Homes Export to Togo

The Advantages of Employing Stainless Steel Fasteners Export to Togo

Top Internal Hex Screw Prices in Latvia Revealed

Pump and Valve Castings | Precision Investment Castings

Key Questions to Ask When Selecting High-Performance Antimagnetic Spring Washers

How to Choose High-Quality Antimagnetic Spring Washers?

The Advantages of Utilizing External Hex Flange Screws Export to Canada

Butterfly valves play a crucial role in the oil and gas industry by controlling the flow of oil, gas, and other fluids in pipelines and storage tanks. Their compact design and quick operation make them suitable for high-pressure applications, ensuring the safe and efficient transport of valuable resources. Additionally, butterfly valves are used in emergency shut-off systems to prevent leaks and spills in case of accidents.

### 4. Food and Beverage Processing.

In food and beverage processing plants, butterfly valves are used to regulate the flow of ingredients, liquids, and gases in production lines. These valves are designed to meet strict hygiene standards and prevent contamination in food processing facilities. With advancements in materials and designs, butterfly valves have become indispensable in ensuring the quality and safety of food products.

### Conclusion.

Butterfly valves have undoubtedly transformed industries by providing efficient and reliable flow control solutions for various applications. Their innovative designs, materials, and functionalities continue to drive advancements in industrial processes, leading to increased productivity and sustainability. As industries evolve, butterfly valves will remain key components in optimizing operations and meeting the changing demands of the market.

Contact us to discuss your requirements of what is a butterfly valve, ball type control valve, flow control valve design. Our experienced sales team can help you identify the options that best suit your needs.

Additional reading:How Will UAE's Flange Screws Impact Trade?

Key Questions to Ask When Selecting Custom Fastener Coating for Optimal Durability

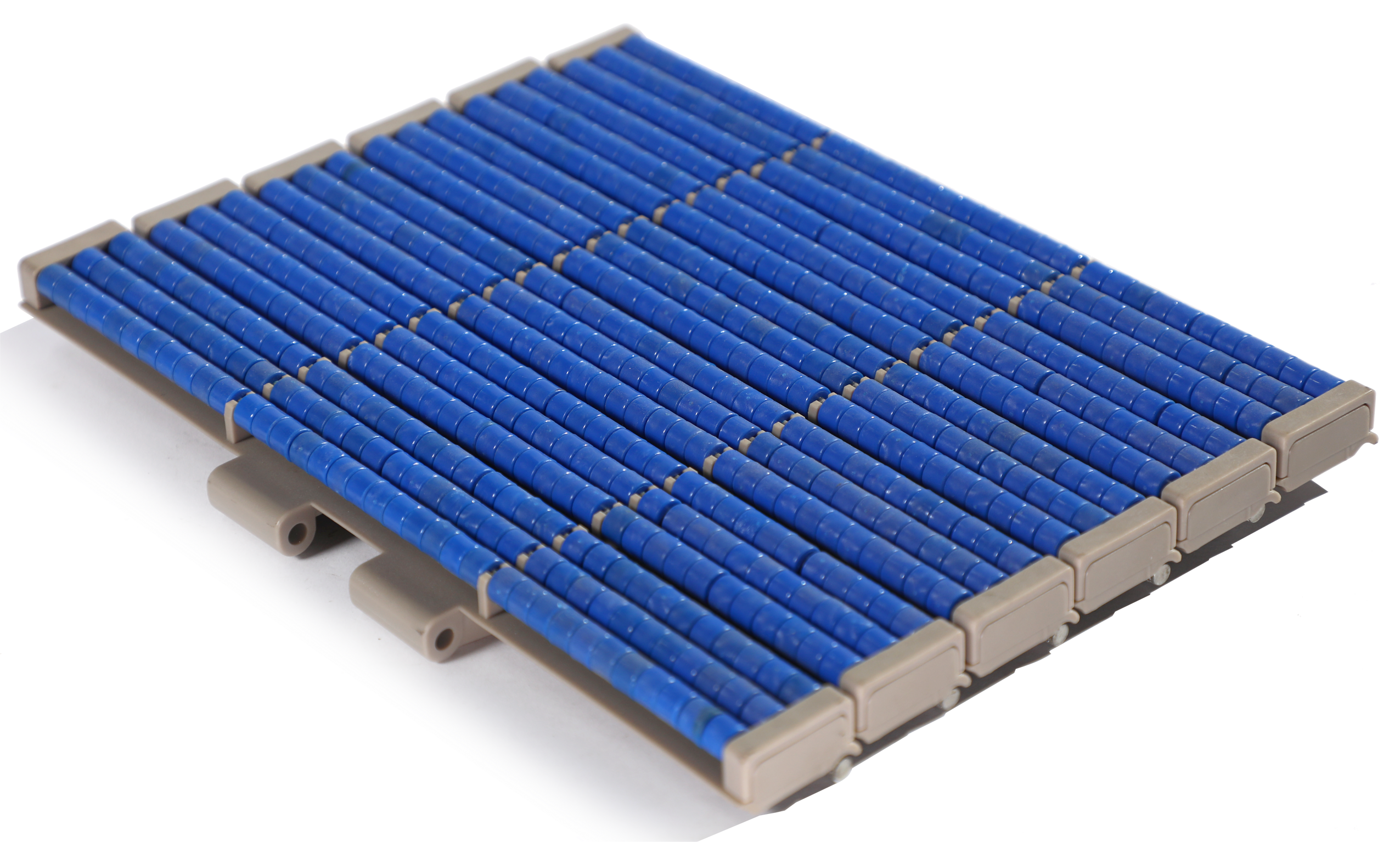

Feeder tape size

Swing Check Valve - Diagram, Types, and Applications

How to Determine Internal Hex Screw Cost in Laos?

The Advantages of Choosing Internal Hex Screw Suppliers in Indonesia

Key Questions to Ask When Considering the Cost of External Hex Screw in Argentina