What are the Key Questions to Ask When Ordering gate valve greasing?

When ordering gate valve greasinggate valve greasing, there are several key questions that should be asked to ensure the proper maintenance and functioning of the valves. The first and most important question to ask is what type of grease is recommended for the specific type of gate valve being used. .

The type of grease required for a gate valve will depend on several factors, such as the material of the valve, the pressure and temperature of the system, and the operating environment. Different types of grease have different properties, such as viscosity, adhesion, and resistance to high temperatures, so it is important to choose the right grease for the job.

In addition to the type of grease, it is also important to ask how often the gate valve should be greased. Over-greasing can cause valves to become clogged or sticky, while under-greasing can lead to increased wear and tear. By following the manufacturer's recommendations for greasing intervals, you can ensure that your gate valves are properly maintained and operate smoothly.

Another key question to consider is how the grease should be applied to the gate valve. Some valves may have specific grease fittings or ports that require special tools for greasing, while others may need to be disassembled for greasing. By understanding the proper greasing procedure, you can avoid damaging the valve and ensure that the grease is applied correctly.

Additional reading:The Advantages of Installing Solar Panels in Homes Export to Togo

The Advantages of Employing Stainless Steel Fasteners Export to Togo

Top Internal Hex Screw Prices in Latvia Revealed

Pump and Valve Castings | Precision Investment Castings

Key Questions to Ask When Selecting High-Performance Antimagnetic Spring Washers

How to Choose High-Quality Antimagnetic Spring Washers?

The Advantages of Utilizing External Hex Flange Screws Export to Canada

Finally, it is important to ask about the effects of greasing on the performance of the gate valve. Properly greasing a valve can help to reduce friction, prevent leaks, and extend the lifespan of the valve. By regularly greasing your gate valves, you can improve their efficiency and reliability, ultimately saving time and money on repairs and replacements.

In conclusion, asking the right questions when ordering gate valve greasing is essential for maintaining the proper functioning of your valves. By understanding the type of grease needed, the greasing intervals, the greasing procedure, and the effects of greasing, you can ensure that your gate valves operate smoothly and efficiently. With proper maintenance and greasing, you can extend the lifespan of your valves and avoid costly repairs in the future.

If you are looking for more details, kindly visit pressure control valve, gate valve and butterfly valve difference.

Additional reading:How Will UAE's Flange Screws Impact Trade?

Key Questions to Ask When Selecting Custom Fastener Coating for Optimal Durability

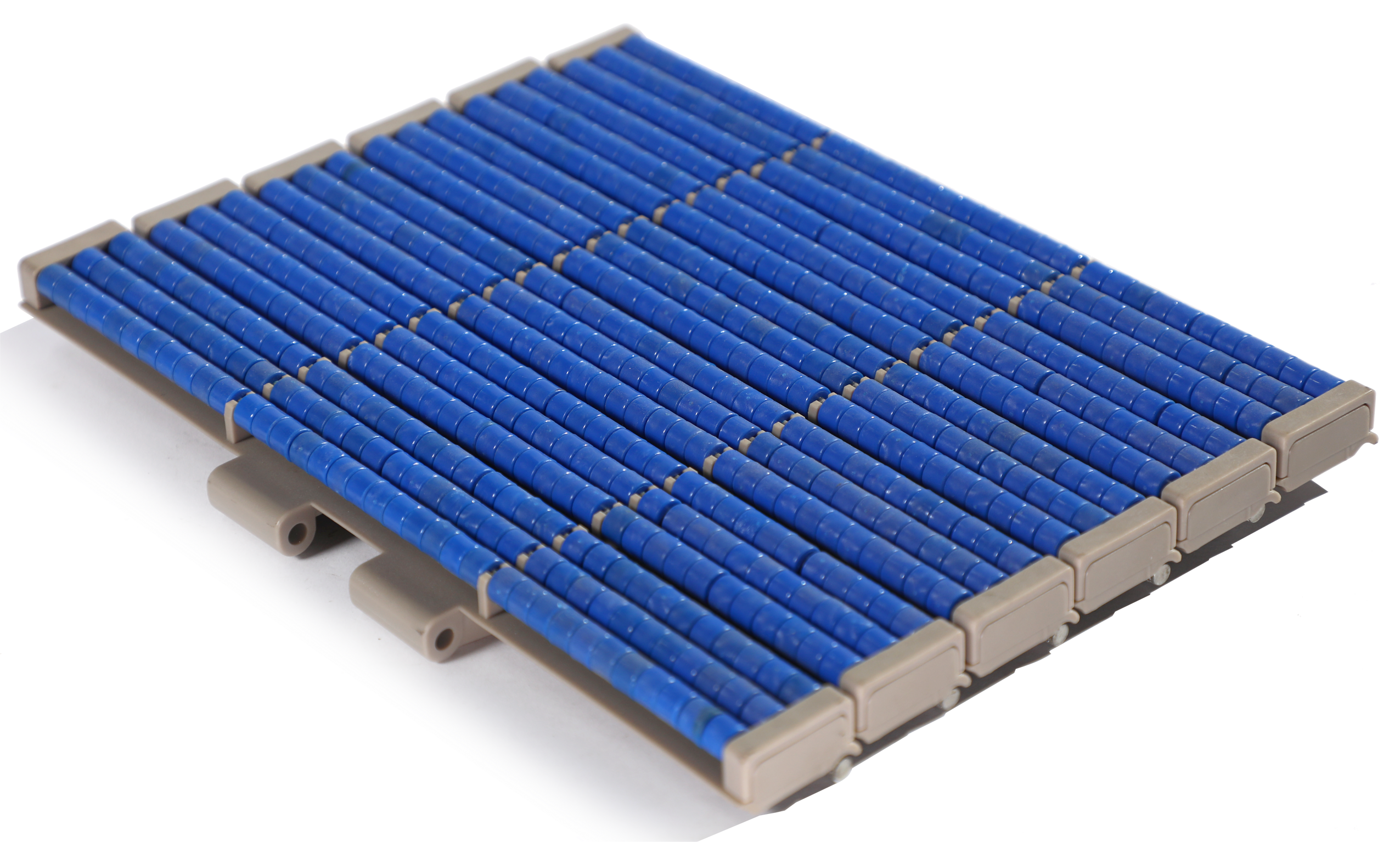

Feeder tape size

Swing Check Valve - Diagram, Types, and Applications

How to Determine Internal Hex Screw Cost in Laos?

The Advantages of Choosing Internal Hex Screw Suppliers in Indonesia

Key Questions to Ask When Considering the Cost of External Hex Screw in Argentina