Mastering Shape Moulding Machine: A Comprehensive Guide

**Q&A: Mastering Shape Moulding Machine **.

**Q: What is a shape moulding machine?**.

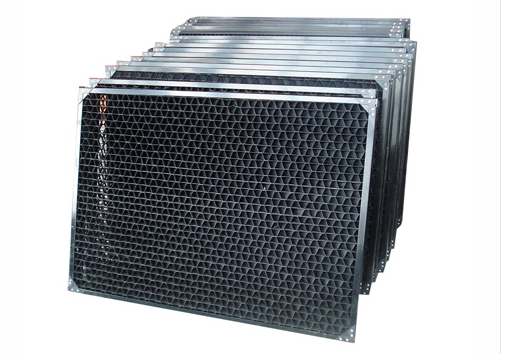

A: A shape moulding machine is a piece of equipment used in the manufacturing industry to create a variety of shapes and forms from materials such as foam, plastic, or metal. These machines work by heating up the material until it becomes pliable, then pressing it into a mould to give it a specific shape.

**Q: How does a shape moulding machine work?**.

A: A shape moulding machine works by first heating up the material to its melting point. This can be done using a variety of methods, such as infrared heating or steam. Once the material is heated, it is then injected into a mould cavity where it is cooled and solidified. The mould is then opened, and the newly formed shape is removed and ready for further processing.

**Q: What are some common applications of shape moulding machines?**.

Additional reading:How do you use a honey knife?

Unraveling the Benefits of Twisted Fiber Imports

What is the current price for urea?

Best Non Adjustable Syringe for B2B Purchases: Why Choose?

Are custom waterproof patio furniture covers worth buying?

What is the cost of PCE admixture?

How do you make water soluble NPK fertilizer?

A: Shape moulding machines are commonly used in the production of packaging materials, insulation products, and even decorative items. Foam shapes produced by these machines are widely used in the packaging industry for cushioning and protecting delicate items during transportation. In the construction industry, shape moulding machines are used to produce insulation panels that help regulate temperature and reduce energy costs.

**Q: How can one master the operation of a shape moulding machine?**.

A: To master the operation of a shape moulding machine, one must first receive proper training on how to safely operate the equipment. Additionally, it is important to understand the different settings and controls of the machine, as well as the properties of the material being used. Regular maintenance and cleaning of the machine are also essential to ensure smooth operation and longevity.

**Q: Are there any tips for troubleshooting common issues with a shape moulding machine?**.

A: When troubleshooting common issues with a shape moulding machine, it is important to first identify the problem accurately. This may involve checking for clogs in the material feed system, ensuring proper temperature settings, and inspecting the mould for any damage. Keeping a record of maintenance and repairs can also help in identifying recurring issues and preventing them in the future. Consulting with the manufacturer or a qualified technician may also be necessary for more complex problems.

In conclusion, mastering the operation of a shape moulding machine requires a combination of proper training, understanding of the equipment and materials, and regular maintenance. By following these guidelines and being proactive in addressing issues, one can successfully operate a shape moulding machine and produce high-quality products.

If you want to learn more, please visit our website How much does the lost foam casting equipment, Sand temperature regulator, Automatic lost foam casting production line.

Additional reading:Which is the top-rated animal husbandry apparatus for purchase?

How long do canvas canopies last?

Is redispersible polymer exporting the key to sustainability?

Unlocking the Benefits of Triple Super Phosphate: Everything You Need to Know

Top Beekeeping Tools on Sale - Buy Today!

CMC: Unleashing the Power of Creativity?

Save Money on Ear Tag Applicator Costs