Revolutionize Your Manufacturing Process with Cylindrical Lithium Battery Pack Assembly

Revolutionize Your Manufacturing Process with Cylindrical Lithium Battery Pack Assembly.

Are you looking for a way to streamline your manufacturing process and increase efficiency? Look no further than cylindrical lithium battery pack assembly. This innovative technology has the power to revolutionize the way you manufacture batteries, leading to significant time and cost savings.

The primary reason why cylindrical lithium battery pack assembly is so effective is because it allows for a more compact and efficient design. By using cylindrical cells instead of traditional prismatic cells, manufacturers can pack more energy into a smaller space. This means that you can create batteries that are smaller and lighter, while still providing the same level of power. Additionally, the cylindrical design allows for easier and more efficient assembly, resulting in faster production times and lower labor costs.

Furthermore, cylindrical lithium battery pack assembly offers improved safety and reliability compared to other types of battery assembly. Cylindrical cells are inherently more stable and less prone to thermal runaway, reducing the risk of fires and explosions. This makes them ideal for use in high-risk environments or applications where safety is a top priority. Additionally, the cylindrical design allows for better heat dissipation, prolonging the lifespan of the battery and ensuring consistent performance over time.

Additional reading:Unlocking the Benefits of Mixed Plastic Baler for Eco-Friendly Recycling

Solving Zambia's Flour Business Needs with Advanced Flour Machine Technology

5 Tips for Successful Chakki Atta Plant Care & Maintenance

How to choose the best steel sheet plating machine line?

Choosing the Best Manual Flour Packing Machine in India

Revolutionizing Warehouse Operations with Robot Pallets: How?

Revolutionary Destoner: Transforming the Grain Industry?

The benefits of cylindrical lithium battery pack assembly extend beyond just manufacturing efficiency. By using this advanced technology, manufacturers can also reduce their environmental footprint. Cylindrical cells are more easily recyclable compared to other types of cells, making them a more sustainable choice for battery production. This means that companies can not only improve their bottom line, but also contribute to a cleaner and healthier planet.

In conclusion, cylindrical lithium battery pack assembly has the potential to revolutionize the manufacturing process for batteries. With its compact design, improved safety and reliability, and environmental benefits, it offers a smart solution for companies looking to optimize their production processes. By leveraging this innovative technology, manufacturers can enjoy increased efficiency, lower costs, and a greener approach to battery production. Embrace the power of cylindrical lithium battery pack assembly and take your manufacturing process to the next level.

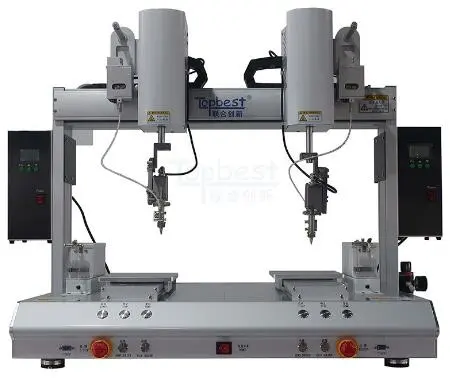

Contact us to discuss your requirements of battery module assembly line supplier, Lithium Battery Shell Seal Laser Welding Machine, Battery Pack Assembly Equipment. Our experienced sales team can help you identify the options that best suit your needs.

Additional reading:Revolutionizing Agriculture: Maize Vibro Separator Innovations

Comparing Hebei Pingle Flour Machinery to Competitors: A Guide

Ultimate Guide to PCB Etching Machine: Top FAQs Answered

Ultimate Guide to Using Pallet Strapper Machine

Why Your Warehouse Needs a Rotary Arm Pallet Wrapping Machine

How to Choose the Right Concrete Batching Plant for My Construction Project?

Are Fiber Laser Cutting Machines the Future of Precision Manufacturing?