What is Thermite Welding Often Used In?

Thermite welding, also known as exothermic welding, is a specialized welding process that finds application in various industries. In this article, we will explore the diverse range of areas where thermite welding is often employed, highlighting its significance and benefits in each context.

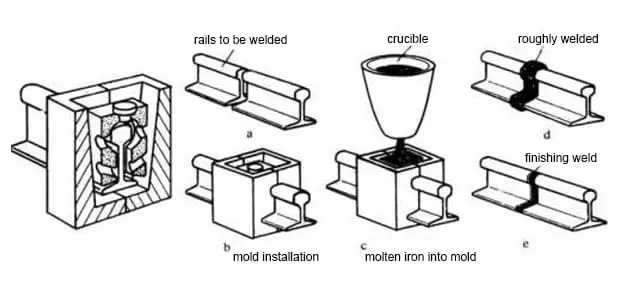

Railway Construction and Maintenance

One of the primary areas where thermite welding is extensively utilized is in railway construction and maintenance. The process offers several advantages that make it particularly well-suited for joining railway tracks. Thermite welding allows for the creation of continuous and seamless connections between rail sections, ensuring smooth and efficient train operations.

Thermite welding plays a crucial role in railway infrastructure projects, such as the installation of new tracks and the repair of damaged sections. It enables the formation of robust and durable welds that can withstand heavy loads and extreme weather conditions. The high-quality welds produced through thermite welding provide excellent electrical conductivity and help maintain the integrity of the railway network.

Pipeline Construction

Another prominent application of thermite welding is in the construction of pipelines, especially those that transport flammable or hazardous substances. Thermite welding ensures secure and leak-proof connections between pipeline segments, minimizing the risk of accidents and environmental hazards.

The ability of thermite welding to create strong and reliable joints makes it an ideal choice for pipelines that operate under high pressure. By eliminating the need for additional fittings or mechanical connections, thermite welding enhances the overall structural integrity of the pipeline system.

Electrical Grounding Systems

Thermite welding plays a vital role in establishing effective electrical grounding systems. These systems are crucial for electrical safety and the protection of personnel and equipment in various settings, including power stations, substations, and industrial facilities.

Additional reading:Why is Desulphurization Pump the Unsung Hero of Clean Air?

Frequently Asked Questions about Centrifugal Pumps

What are the different types of mini ball valves?

What is block forging?

Everything You Need To Know about Multistage Centrifugal Pumps

The role of ball bearing lubrication and the method of oil lubrication

How to install Flexible Metal Conduit

Thermite welding enables the creation of low-resistance connections between conductive materials, ensuring efficient dissipation of electrical currents into the ground. The high conductivity and durability of thermite welds make them ideal for long-lasting and reliable grounding systems.

Shipbuilding and Marine Applications

In the realm of shipbuilding and marine engineering, thermite welding offers unique advantages. The process is used for joining various metal components in ship construction, including hull sections, structural supports, and pipe connections.

Thermite welding in shipbuilding ensures strong and watertight joints, contributing to the overall structural integrity and safety of vessels. The high-strength welds produced through this method withstand the harsh marine environment, including exposure to saltwater, extreme temperatures, and vibrations.

Other Industrial Applications

Thermite welding finds application in a range of other industrial sectors. It is utilized in the fabrication of heavy machinery, such as mining equipment and cranes, where robust welds are crucial for reliable performance under demanding conditions.

Moreover, thermite welding plays a role in the repair and maintenance of large-scale industrial equipment, including steel structures, pipelines, and storage tanks. Its ability to create welds with excellent mechanical properties makes it a preferred choice for restoring the structural integrity of such equipment.

Conclusion

In conclusion, thermite welding is a versatile and widely employed welding process that finds application in various industries. Its significance can be observed in railway construction, pipeline systems, electrical grounding, shipbuilding, and numerous other industrial contexts. By providing strong and durable welds, thermite welding contributes to the integrity, safety, and efficiency of diverse structures and systems. Understanding the applications of thermite welding allows industries to harness its benefits and make informed choices for their specific welding requirements.

Additional reading:What is the purpose of airless spray gun filters?

How do you identify a thrust bearing?

Where do you use a bellows seal gate valve?

What is medical injection molding?

What is the average lifespan of Water Well Drill Pipe?

Top 5 Tips for Selecting a Reliable Longhe Attachment Contractor - Which One Will Ensure Your Project's Success?

Master Custom Reducer: The Ultimate Solution to Google's Hottest Questions